Innovations

At SmartBuilding our main concern is the continuous development and improvement of structural systems and construction methods, always with safety and affordable prices in mind.

Αρχική » Eco-Technologies » Innovations

Here are some of the innovations we implement in our building systems.

Masonry

In all our construction projects, whether they are made of reinforced concrete or metal frame, we never “wedge” the masonry directly onto the frame. In our buildings, we line the surface of the frame around its perimeter with extruded polystyrene (a joint of a specific width, as defined in the approved static adequacy study, usually measuring 2cm) and then we place the bricks or aerated concrete masonry elements (Ytong, Alfa Block) and dry construction systems.

Dry construction

What does the dry building system consist of:

- Frames (galvanized sheet profiles): uprights, cross-pieces, rafters & purlins, roof channels, L-corners.

- Standard boards: plaster boards, cement boards, mineral fibers. Fasteners: screws, hangers, plugs, angle caps, fasteners.

- Insulating materials: mineral wool, expanded and extruded polystyrene.

- Jointing materials: glues, putties, tapes, gauzes, paints.

Tiers

We NEVER attach reinforced concrete tiers directly onto the beams, either by welding or “hammering” their reinforcements onto the supporting elements, but we place some special, additional supporting pieces made of galvanized steel elements with an elastic seal (gasket) made of neoprene sheets.

Reinforced concrete shear walls

In purely metal constructions and only in industrial buildings, the rigidity elements (windbreaks, bracings, cross-links, etc.) are made of steel cross-sections. However, in the construction of metal-building houses, the use of windbreaks usually creates various architectural problems, which require complex procedures and techniques for the correct and safe integration of the masonry. For this reason, the rigidity elements we use at Smart Building are custom-made reinforced concrete walls (shear walls).

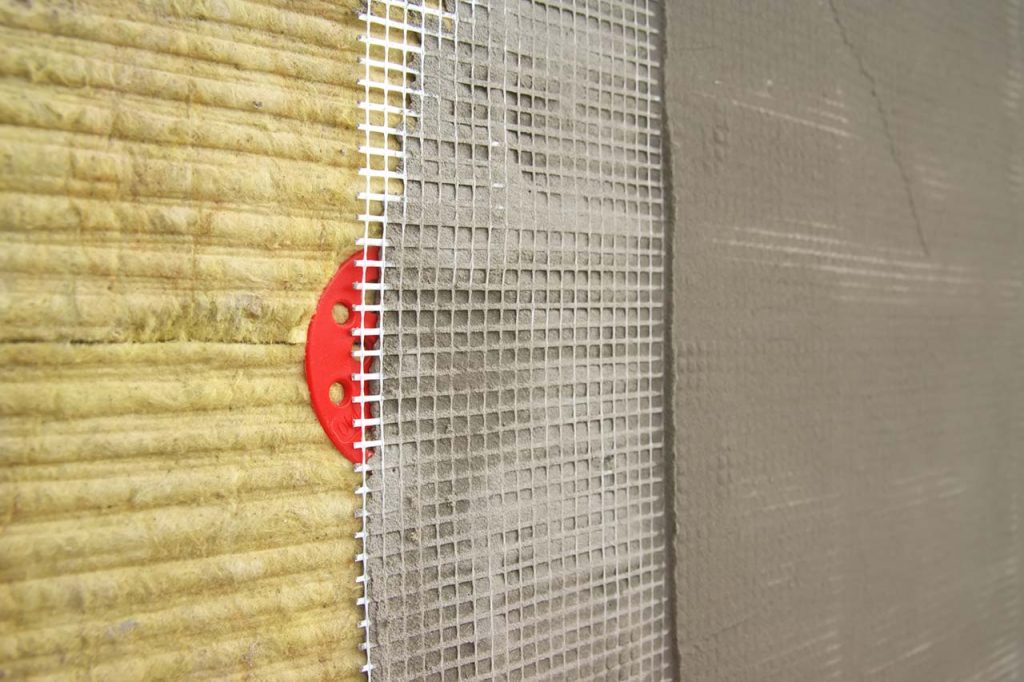

Fire-resistant thermal facade

It is an external thermal facade system with non-combustible stone wool as its thermal insulation material.

Real-Life Advantages:

- Optimal fire protection. The inorganic composition of the material ranks in the highest possible non-combustible category – A1, according to the EN 13501-1 standard.

- Maximum protection of facades from climatic stress.

- Flexibility in the final configuration of the appearance (texture, coloring).

The fibers of the material are properly processed making it extremely hydrophobic so that it does not absorb water. Combined with the low coefficient of resistance to water vapor diffusion, it allows the immediate evaporation of even the slightest moisture, keeping the thermal insulation capacity of the material constant, with favorable conditions of the building envelope and passive ventilation of the structure.

- The immobilized air within the slab mass ensures a low coefficient of thermal conductivity.

- Its surface structure ensures excellent fixing of the material with both adhesives and plastering mortars, while the cohesion of the material makes it impact resistant.

- Sound insulation.

Contact us

Contact us and we will get back to you soon.