Κατασκευαστική εταιρεία

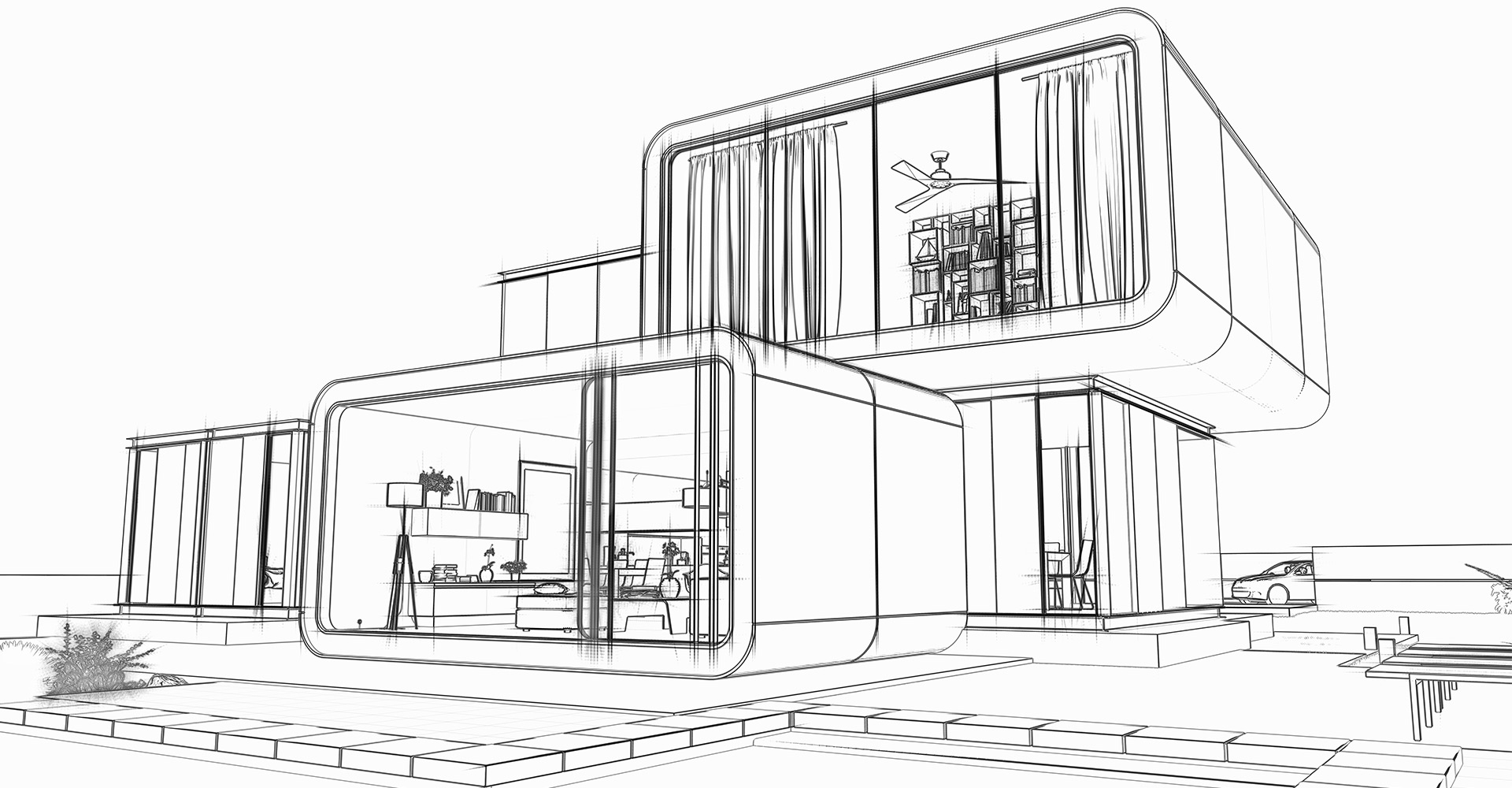

Smart Building

Η Smart Building αποτελεί μια σύγχρονη τεχνική κατασκευαστική εταιρεία με έδρα την Αθήνα. Εξειδίκευση στην κατασκευή κατοικιών και κτιρίων.

Η Smart Building αποτελεί μια σύγχρονη τεχνική κατασκευαστική εταιρεία με έδρα την Αθήνα. Εξειδίκευση στην κατασκευή κατοικιών και κτιρίων.

Στη SMART BUILDING οι δικές σας προσδοκίες είναι οι δικοί μας στόχοι.

Η Smart Building αποτελεί μια σύγχρονη τεχνική κατασκευαστική εταιρεία με έδρα την Αθήνα. Αποτελούμενη από άριστα εκπαιδευμένους και πιστοποιημένους επαγγελματίες, είναι σε θέση να αναλάβει την ολοκληρωμένη μελέτη και την κατασκευή οποιουδήποτε έργου. Με έμφαση στην άμεση ανταπόκριση, την εξασφάλιση κτιρίων άριστης ποιότητας και αισθητικής και φυσικά το προσιτό κόστος, καταφέρνουμε να παρέχουμε εγγυημένες λύσεις σε κάθε μας πελάτη.

Η Smart Building S.A. πρόκειται για μια καινοτόμο τεχνική κατασκευαστική εταιρεία με εξειδίκευση στα συστήματα δόμησης σύμμεικτης κατασκευής, καλύπτοντας παράλληλα και όλο το φάσμα των κατασκευών. Το έμπειρο προσωπικό μας είναι σε θέση να αναλάβει οποιαδήποτε συμβατική ή σύμμεικτη κατασκευή, επισκευές – ενισχύσεις, μεταλλικά σπίτια, επαγγελματικά κτήρια κλπ. με απόλυτη επιτυχία.

Η πολυετής μας εμπειρία στις κατασκευές σπιτιών μας επιτρέπει να εξασφαλίσουμε κτίρια άριστης αντοχής, απόλυτα αντισεισμικά και κατάλληλα να στεγάσουν και να θωρακίσουν τα όνειρά σας. Τα συστήματα δόμησης που σας προσφέρουμε είναι δυνατό να εφαρμοσθούν σε οποιαδήποτε περιοχή της Ελλάδος και να προσαρμοσθούν σε οποιαδήποτε αρχιτεκτονική μελέτη, λόγω της ευελιξίας του μεταλλικού σκελετού. Με μεγάλες δυνατότητες μετατροπών και παρεμβάσεων, τα κτίρια μας εγγυώνται πάντα την ικανοποίηση των οικιστικών σας αναγκών και την ασφάλεια σας.

Στην μέχρι τώρα πορεία μας στον χώρο των κατασκευών έχουμε υλοποιήσει έναν μεγάλο αριθμό έργων, ικανοποιώντας τις ανάγκες των πελατών μας στον υπέρτατο βαθμό. Ως πιστοποιημένη κατασκευαστική εταιρεία, η Smart Building αναλαμβάνει να ολοκληρώσει κάθε έργο δόμησης παρέχοντας όλες τις απαραίτητες εγγυήσεις ασφάλειας και ποιότητας. Η έδρα μας βρίσκεται στην Αθήνα ωστόσο έχουμε υλοποιήσει μια πληθώρα κατασκευαστικών έργων σε όλες τις περιοχές της Ελλάδος. Δείτε μερικά δείγματα από τις δουλειές μας και σίγουρα θα πειστείτε για το αποτέλεσμα που σας παρέχουμε.

Βασικός μας στόχος είναι να παρέχουμε ολοκληρωμένες υπηρεσίες που θα καλύψουν κάθε σας ανάγκη. Στα πλαίσια του αντικειμένου δραστηριότητάς μας αναλαμβάνουμε ένα ευρύ φάσμα εργασιών, από την αρχική μελέτη και τις χωματουργικές εργασίες μέχρι την κατασκευή σπιτιών και επαγγελματικών χώρων άριστης ποιότητας και εντυπωσιακού αρχιτεκτονικού σχεδιασμού. Με ιδιαίτερη έμφαση στην άριστη λειτουργικότητα και την τεράστια αντοχή κάθε μας κατασκευής, η κατασκευαστική εταιρεία Smart Building ολοκληρώνει κάθε έργο με τον πλέον κατάλληλο και αποτελεσματικό τρόπο.

Στην Smart Building σας προσφέρουμε τις πιο προσιτές τιμές της αγοράς δίνοντάς σας μάλιστα την δυνατότητα για υπολογισμό του κόστους, πριν την έναρξη των εργασιών και μέσα από την ιστοσελίδα μας.

Εξειδικευόμαστε στις κατασκευές κτιρίων με όλα τα σύγχρονα συστήματα δόμησης, καταφέρνοντας έτσι να προσφέρουμε την πιο αποδοτική λύση βάση των δικών σας μοναδικών αναγκών.

Η διαδικασία για την κατασκευή σπιτιού περιλαμβάνει ένα ευρύ φάσμα επιμέρους εργασιών, οι οποίες μάλιστα πρέπει να πραγματοποιηθούν από έμπειρους και άρτια καταρτισμένος επαγγελματίες.

Συνέπεια, επαγγελματισμός, προσιτό κόστος και εγγυημένα αποτελέσματα είναι μόνο μερικοί από τους λόγους για να επιλέξετε την τεχνική κατασκευαστική εταιρεία Smart Building στην Αθήνα.

Βασική μας φιλοσοφία είναι ότι προκειμένου ένα σπίτι να «αξίζει» τα λεφτά του πρέπει να πληροί συγκεκριμένες τεχνικές και αισθητικές προδιαγραφές. Έτσι, σε κάθε κατασκευή σπιτιού που αναλαμβάνει η κατασκευαστική εταιρεία μας φροντίζουμε το τελικό αποτέλεσμα να ακολουθεί μερικούς βασικούς κανόνες:

Η τεχνική κατασκευαστική εταιρεία Smart Building μένει διαρκώς ενημερωμένη σε όλα τα σύγχρονα συστήματα δόμησης. Οι εξειδικευμένοι μας επαγγελματίες είναι σε θέση να προσφέρουμε μοναδικές καινοτομίες που εξασφαλίζουν οικολογικά σπίτια και κτίρια άριστης ενεργειακής απόδοσης, μηδενικής κατανάλωσης ενέργειας και εξαιρετικής πυροπροστασίας. Μένοντας μπροστά από τον ανταγωνισμό, έχουμε αναπτύξει τεχνολογίες που θα προσφέρουν τεράστια οφέλη σε εσάς και τον χώρο που θα μείνετε. Αναλυτικότερα, οι οικολογικές κατασκευές και οι τεχνολογίες που σας παρέχουμε είναι:

Τα ενεργειακά σπίτια μηδενικής κατανάλωσης Smart Zero αποτελούν μια καινοτομία της Smart Building με χαμηλή έως μηδενική κατανάλωση ενέργειας.

Οι παθητικές κατασκευές της σειράς Smart Passive παρέχουν μεγάλη θερμική άνεση καθ’ όλη τη διάρκεια του έτους για μια υγιεινή διαβίωση χωρίς υγρασία.

Οι κατοικίες ενεργειακής κλάσης Α+ που σας παρέχουμε προσφέρουν εξαιρετικά πλεονεκτήματα στην εξοικονόμηση ενέργειας και χρημάτων.

Τα οικολογικά σπίτια Smart Eco αποτελούν μια ιδιαίτερα προσιτή και ταυτόχρονα αξιόπιστη λύση στην κατασκευή σπιτιού της Smart Building.

Δευ - Πάρ / 9:00πμ - 5:00μμ