Composite construction

Composite construction is a modern way of building. It is based on the cooperation of steel sections and reinforced concrete.

Αρχική » Building Systems » Composite construction

Composite construction is defined as a modern building method based on the cooperation of steel sections (metal elements) and reinforced concrete elements.

The use of composite construction method with a metal bearing body offers significant advantages over conventional, prefabricated construction, as metal elements are utilized to the maximum extent, for the benefit of the entire construction.

The flexibility of composite construction allows full implementation of the architectural plans as outlined in the building permit. Moreover, thanks to its state-of-the-art technology, it encompasses anti-seismic protection – something that cannot be met by conventional types of construction.

Composite structures for houses

Composite structures in house construction utilize metal load-bearing structures, resulting in metal building houses with excellent technical specifications and enormous benefits. This is why metal composite construction is one of the most dynamic fields in the house construction industry, achieving fast, quality, and affordable results.

The difference between composite and conventional construction houses lies in the very frame of the building.

In conventional buildings, the house frame is made of reinforced concrete, while in composite structures it is made of metal.

Advantages of composite construction

There are a good number of advantages in composite construction compared to conventional building methods. The main ones are:

- Earthquake resistance (anti-seismic). The columns and beams are made of steel sections, shielding the building against seismic vibrations. In fact, this particular method of construction is recommended internationally and also in Greece, especially in areas with intense seismic activity, due to its high resistance in the event of an earthquake.

- High Technical Specifications. The composite construction method ensures stable, high construction standards because the members of the load-bearing body (Metal Beams – Metal Columns) are industrially made by certified manufacturers.

- Freedom of architectural design. It allows the creation of large single spaces without intermediate columns, something that cannot be realized in standard prefabricated (prefab) constructions that demand limited openings.

- Recommended for the construction of multi-storey buildings – mainly because it allows the construction of high-rise buildings without the use of oversized metal elements.

- Ideal for height extension. Composite construction favors height expansion, due to lower superstructure weight.

- Shorter delivery time. It is estimated that the time needed for the completion of a project is approximately half than for conventional constructions built with a load-bearing body made of reinforced concrete.

- Lower social security costs. The amount of the social security levy is 50% less than in conventional constructions.

- Lower foundation building costs. The comparatively small loads imposed on the foundation, result in lower costs.

- No shipping costs. In composite construction, the steel frame is manufactured on-site and erected within a few hours right on the property.

- Easy damage repair. Any wear or damage that occurs can be easily repaired.

- Construction method used in all the big-size Olympic Games venues for Athens 2004.

It is evident that the benefits of composite construction for houses or other buildings surpass other methods. It is thus no coincidence that in recent years more and more homeowners prefer this option.

Disadvantages of composite construction

It can easily be said that the one disadvantage of composite construction is that it’s just recently started growing in Greece, so it’s not widespread yet. At present, it’s mainly adopted by homeowners who are looking for a modern method of building construction. As a result, there are just a few certified companies offering composite construction with satisfactory results.

However, there is no need to worry, since Smart Building company is a certified manufacturer in Greece with many years of experience and excellent expertise in the implementation of composite constructions.

Our long list of successful projects is our guarantee for optimal results in the construction of your dream home or ideal building.

Delivery time for composite construction houses

The process of issuing a building permit includes a series of actions. The first and most basic step for us is to determine the work required as dictated by the future owner, so as to decide the type of building permit required.

Afterward, our staff will visit the property in order to take all the necessary photos and record all the essential information which will determine the legislative framework that covers the desired constructions.

After these procedures are completed, the steps that follow are:

- Submission of all mandatory documentation and architectural planning study

- Control of compliance with general and location-specific urban planning provisions and specifications.

- Submission of static efficiency study and other relevant technical planning studies

- Official check of compliance with specifications and regulations

- Tax compliance check and payment

How are composite structures made?

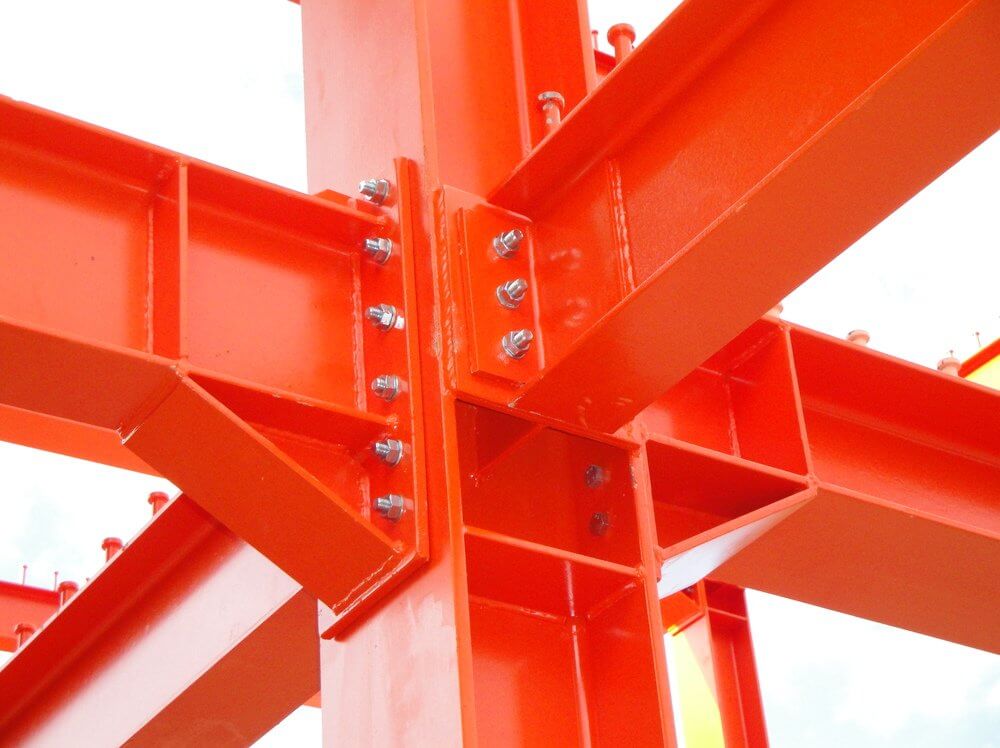

In order to build a composite structure, it is necessary to connect the metal framing (columns, beams, and diagonal stiffeners) with bolted connections. This makes the final form of the building’s supporting body.

Then, reinforced concrete is used for the construction of the slabs, while concreting can be done in steel formwork or wooden formwork as in conventional constructions.

This is followed by plastering of the full-length slab or painting of the pre-slabs.

In order to achieve the perfect working together of the metal elements and the concrete, we place shear piles in the upper footing of the beams.

Finally, under the steel formwork, we place either plasterboard or cement board for interior or exterior spaces accordingly.

After the composite structure is completed, masonry follows.

Masonry in composite construction

There are various methods to build masonry in composite constructions. The main ones applied by the experienced staff of Smart Building are:

Masonry with dry construction

The dry masonry technique starts from the outside to the inside, and consists of:

- Frames (galvanized sheet profiles): uprights, sleepers, roof channel, L-corners.

- Standard boards: plaster boards, cement boards, mineral fibers. Fastening accessories: screws, hangers, plugs, angle caps, fasteners.

- Insulating materials: mineral cotton, expanded and extruded polystyrene.

- Jointing materials: glues, putties, tapes, gauzes, paints.

- Thermal facade, 1 layer of cement board, breathable membrane between the metal frame and the cement board, metal frame, mineral cotton or stone wool, 2 layers of plasterboard 12.5mm thick.

Masonry with ytong

Ytong is an industrial material with heat-insulating properties. The masonry is cavity wall style and is constructed on-site by building the elements and interposing a screed, approximately every 1m. vertically.

The final surface is shaped externally by installing a certified thermal facade system and is 12.5-15cm for the internal walls and 25cm for the external ones.

Masonry with sandwich panels

Sandwich panels are structural elements consisting of two parallel grids and a sheet of self-extinguishing expanded polystyrene between them. The two grids are held parallel to each other by bi-diagonal galvanized bars.

After placing and supporting them between the metal pillars, gravel concrete and plaster are added. The final thickness of the masonry is 15cm for the internal walls and 25 cm for the external.

Masonry with bricks

The external masonry is made with bricks of 18x18x32 (block bricks) and the internal masonry with 12-hole bricks.

The thermal insulation is made on the facade masonry with a certified thermal facade system.

Thermal facade in composite construction

The thermal facade is a key element in every construction – house, business space, and any other type of building – especially with the new requirements that exist (KENAK Building Regulations – New Regulation 244/2012/EU). This new regulation goes along with current energy trends and a number of benefits, ensuring ideal living conditions in interior spaces and money saving from decreased fuel consumption – two key issues in the modern era.

Along these lines, the composite construction thermal facades we manufacture are made according to the highest technical specifications, covering the entire external surface of a building.

During construction, no thermal bridges are created in beams, cantilevers, roofs, and throughout the building shell because all surfaces are covered with the thermal facade system.

External thermal insulation system in existing masonry

- Existing Structure: Any statically adequate existing masonry made of bricks, concrete, etc.

- Insulation material: Expanded polystyrene EPS60 & EPS70 &EPS200 for high waterproof sealing points

- Fixing: With cement-based adhesive and mechanical fixing with plugs

- Basic coating: Organic or inorganic, reinforced with mesh over the entire surface of the masonry in a thickness of 3mm to 5mm

- Top coating: Organic colored coating in various shades and styles or inorganic coating for smooth surfaces ready for painting

Contact us

Contact us and we will get back to you soon.